How to Choose the Right Stainless Steel Sheet Metal for Your Project

Choosing the right stainless steel sheet metal for your project is a crucial decision that can significantly affect both the functionality and aesthetics of your final product. With a variety of grades, finishes, and thicknesses available, it can be overwhelming to determine which type of stainless steel sheet metal best meets your specific needs. Understanding the properties and applications of different stainless steel materials is key to making an informed choice.

In this guide, we will explore the essential factors to consider when selecting stainless steel sheet metal, including corrosion resistance, durability, and manufacturing processes. Whether you are embarking on a small DIY project or a large-scale industrial application, this information will help you navigate the complexities of stainless steel sheet metal selection. By the end, you will be better equipped to choose the most suitable stainless steel sheet metal that aligns with your project requirements.

Understanding the Different Types of Stainless Steel Sheet Metal

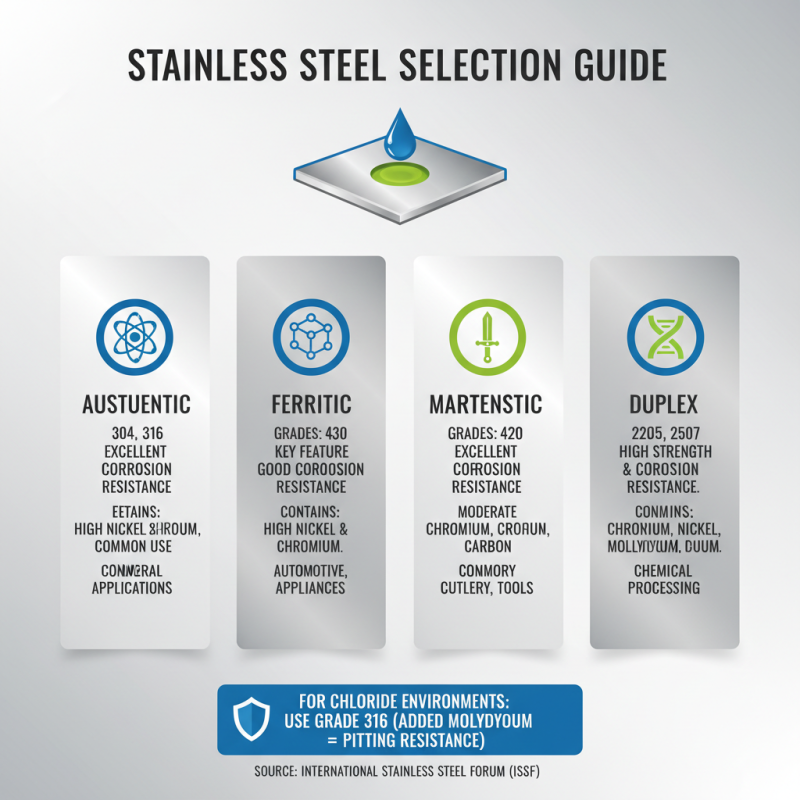

When selecting stainless steel sheet metal for a project, understanding the different types available is crucial. The most common types of stainless steel used in sheet metal fabrication include austenitic, ferritic, and martensitic stainless steels. Austenitic stainless steel, known for its high corrosion resistance and good formability, is often chosen for applications where durability and aesthetic appeal are paramount. It contains high levels of chromium and nickel, making it non-magnetic and suitable for both indoor and outdoor environments.

Ferritic stainless steel, on the other hand, is less ductile than austenitic grades but offers a good balance of strength and corrosion resistance at a lower cost. It is magnetic and is frequently used in automotive applications, kitchen equipment, and industrial settings. Martensitic stainless steels are characterized by their hardness and strength, making them ideal for applications requiring high wear resistance, such as cutlery and tools. However, they are more susceptible to corrosion and are typically used in environments that are less corrosive. By understanding these types, you can make an informed decision on the right stainless steel sheet metal that aligns with your specific project requirements.

How to Choose the Right Stainless Steel Sheet Metal for Your Project

| Type of Stainless Steel | Corrosion Resistance | Mechanical Properties | Common Applications |

|---|---|---|---|

| 304 Stainless Steel | Good | Excellent weldability and formability | Kitchen appliances, food processing |

| 316 Stainless Steel | Very Good | Higher strength at elevated temperatures | Marine environments, chemical processing |

| 430 Stainless Steel | Fair | Decent strength, lower ductility | Automotive trims, appliances |

| Duplex Stainless Steel | Excellent | High strength and toughness | Oil and gas industry, chemical processing |

| Picture Frame Stainless Steel | Good | Flexible for various shapes | Framing, decorative applications |

Key Factors to Consider When Choosing Stainless Steel Thickness

When selecting the appropriate stainless steel thickness for your project, understanding the specific demands of your application is crucial. The thickness of the stainless steel sheet can significantly affect its strength, durability, and overall performance. For instance, thinner sheets may be suitable for applications requiring more flexible or lightweight materials, whereas thicker sheets are often essential in situations where additional strength and resistance to deformation are needed. The internal and external pressures that the material will face should also be considered, as they can dictate the minimum thickness required for safety and functionality.

Another important factor to consider is the environment in which the stainless steel will be used. Corrosive environments, high temperatures, or exposure to harsh chemicals may necessitate a thicker gauge to ensure longevity and stability. Additionally, aesthetic aspects could play a role in your decision if the finish is visible, as thicker materials can sometimes deliver a more substantial and premium look. Ultimately, balancing these factors with the specific requirements of your project will guide you in choosing the right stainless steel sheet metal thickness.

Evaluating the Corrosion Resistance of Stainless Steel Types

When selecting the right stainless steel sheet metal for your project, understanding the corrosion resistance of different stainless steel types is crucial. Stainless steels are categorized into various grades, primarily divided into austenitic, ferritic, martensitic, and duplex types. The most commonly used grades, such as 304 and 316, are austenitic and are known for their excellent corrosion resistance. According to the International Stainless Steel Forum (ISSF), austenitic stainless steels contain a higher percentage of nickel and chromium, which enhance their ability to withstand oxidative environments. In environments exposed to chlorides, grade 316 is often recommended due to its higher molybdenum content, which provides better resistance against pitting corrosion.

While austenitic steels dominate many applications, other types also have their merits. Ferritic stainless steels, for instance, typically show good resistance to stress corrosion cracking in certain conditions, although they may not match the overall corrosion resistance of austenitic grades. A report from the Stainless Steel Development Association highlights that martensitic stainless steels, while less resistant to corrosion, can be used in applications that require both strength and moderate corrosion resistance. Evaluating the specific environmental conditions and potential corrosive agents that the material will encounter is essential in making an informed choice. Extensive corrosion testing and analysis, such as ASTM G48, can provide insights into the performance of these grades under various circumstances, aiding in selecting the most suitable stainless steel sheet for your specific project needs.

How Finish and Surface Treatment Affect Your Project's Needs

When selecting stainless steel sheet metal for your project, understanding how finish and surface treatment can influence the final outcome is crucial. Various surface finishes, such as brushed, polished, and primed, not only enhance the aesthetic appeal but also affect functionality. For instance, a brushed finish can provide a sleek, modern look while offering resistance to fingerprints, making it ideal for appliances and architectural features. Conversely, a polished finish delivers a reflective surface that can easily highlight imperfections, so careful consideration is required based on the application.

Tips: Consider the environment in which the stainless steel will be used. For outdoor applications or areas with high moisture, a finish that offers corrosion resistance is essential. Additionally, if the material will be frequently handled, selecting a finish that reduces wear and tear can prolong the lifespan of the product. Don’t overlook the importance of surface treatment processes such as passivation, which enhances the material's corrosion resistance—crucial for projects exposed to harsh conditions.

Incorporating the right finish can significantly influence your project's maintenance and durability requirements. A matte finish, for example, might suit industrial applications where a low-profile look is desired, while a high-gloss finish could be more suitable for decorative purposes. Always assess your project's specific needs, considering both appearance and the practical benefits of each finish, to make an informed choice that will serve you well in the long run.

Cost vs. Quality: Making a Smart Investment in Stainless Steel Sheets

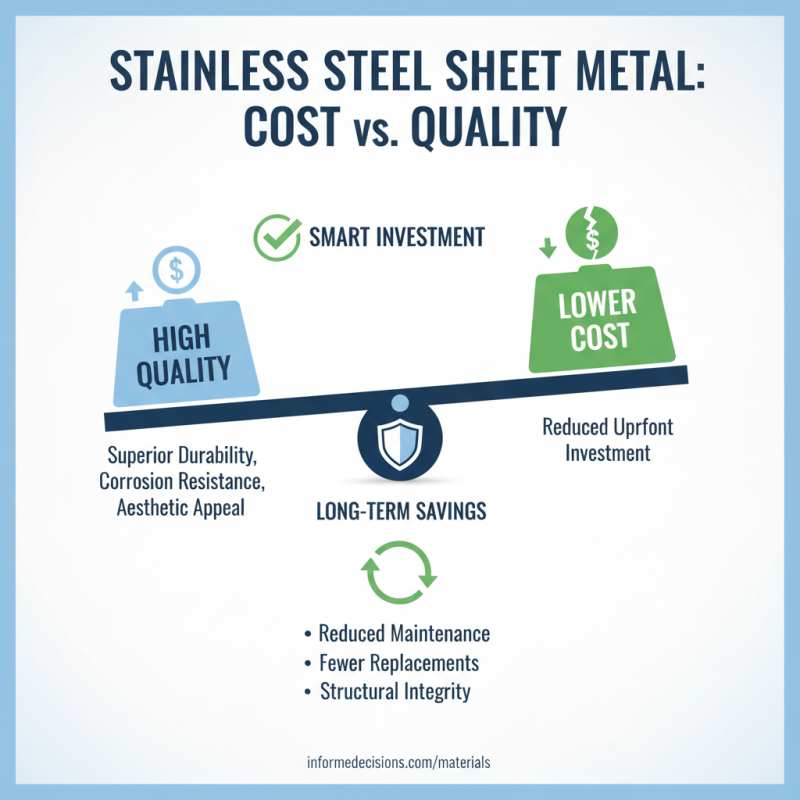

When embarking on a project that requires stainless steel sheet metal, understanding the balance between cost and quality is essential for making an informed decision. High-quality stainless steel sheets, while more expensive upfront, often provide superior durability, corrosion resistance, and aesthetic appeal. Investing in better materials can lead to significant long-term savings by minimizing maintenance costs, reducing the frequency of replacements, and ensuring the structural integrity of your project.

On the other hand, choosing lower-cost options can seem attractive initially, especially for budget-conscious projects. However, these choices may lead to compromised quality, resulting in issues such as rust, warping, or inadequate performance under stress. It's vital to evaluate the specific requirements of your project and consider how much wear the stainless steel will face over time. A well-thought-out investment in quality materials ensures that your project not only meets current demands but also stands the test of time, ultimately providing better value in the long run.

Related Posts

-

2025 How to Choose the Best Aluminum Roof Panels for Your Home Renovation

-

2025 Top Trends in Sheet Metal Fabrication Technology and Applications

-

10 Essential Tips for Choosing the Best Roof Panels for Your Home

-

10 Essential Tips for Setting Up Your Metal Workshop Efficiently

-

Top 5 Benefits of Choosing Aluminum Roofs for Homeowners in 2023 with Industry Insights on Longevity and Energy Efficiency

-

2025 Top 10 Architectural Sheet Metal Trends for Innovative Design Solutions