10 Essential Tips for Setting Up Your Metal Workshop Efficiently

Setting up a metal workshop can be an exciting yet challenging endeavor for both beginners and experienced artisans. A well-organized and efficiently designed metal workshop is crucial for optimizing productivity, safety, and creativity. Whether you are going to work on welding projects, metal fabrication, or intricate detailing, the right setup can significantly enhance your workflow and output quality. With a clear focus on functionality and ease of access, creating a dedicated space for your metal work becomes not only a necessity but also a source of inspiration.

In this article, we present ten essential tips that will guide you in establishing your metal workshop effectively. From selecting the right tools and equipment to maintaining an organized workspace, these tips are designed to help you create an environment that fosters efficiency and safety. Careful planning and attention to detail in your metal workshop design will ensure that you have everything you need at your fingertips, allowing you to focus on your craft without unnecessary interruptions. As you embark on this journey, keep in mind that a streamlined workshop can transform your metalworking experience, making it both productive and enjoyable.

Choosing the Right Space for Your Metal Workshop Setup

When choosing the right space for your metal workshop setup, several factors must be considered to ensure an efficient and productive working environment. Ideally, look for a location that offers ample space to accommodate all your equipment, tools, and materials. A minimum of 200 square feet is recommended, but larger workshops will provide more flexibility and comfort. High ceilings can also be beneficial for operations involving larger machinery or for installing overhead storage solutions.

Ventilation is another critical aspect to keep in mind. Proper airflow is essential to minimize the accumulation of fumes, dust, and other harmful substances generated during metalworking processes. Access to natural light can enhance visibility and make the workspace more inviting, so positioning your shop near windows or installing good lighting fixtures is advisable. Lastly, consider the proximity to resources such as suppliers and support services, as a convenient location can significantly streamline your workflow and improve overall efficiency.

Essential Tools and Equipment Every Metal Workshop Needs

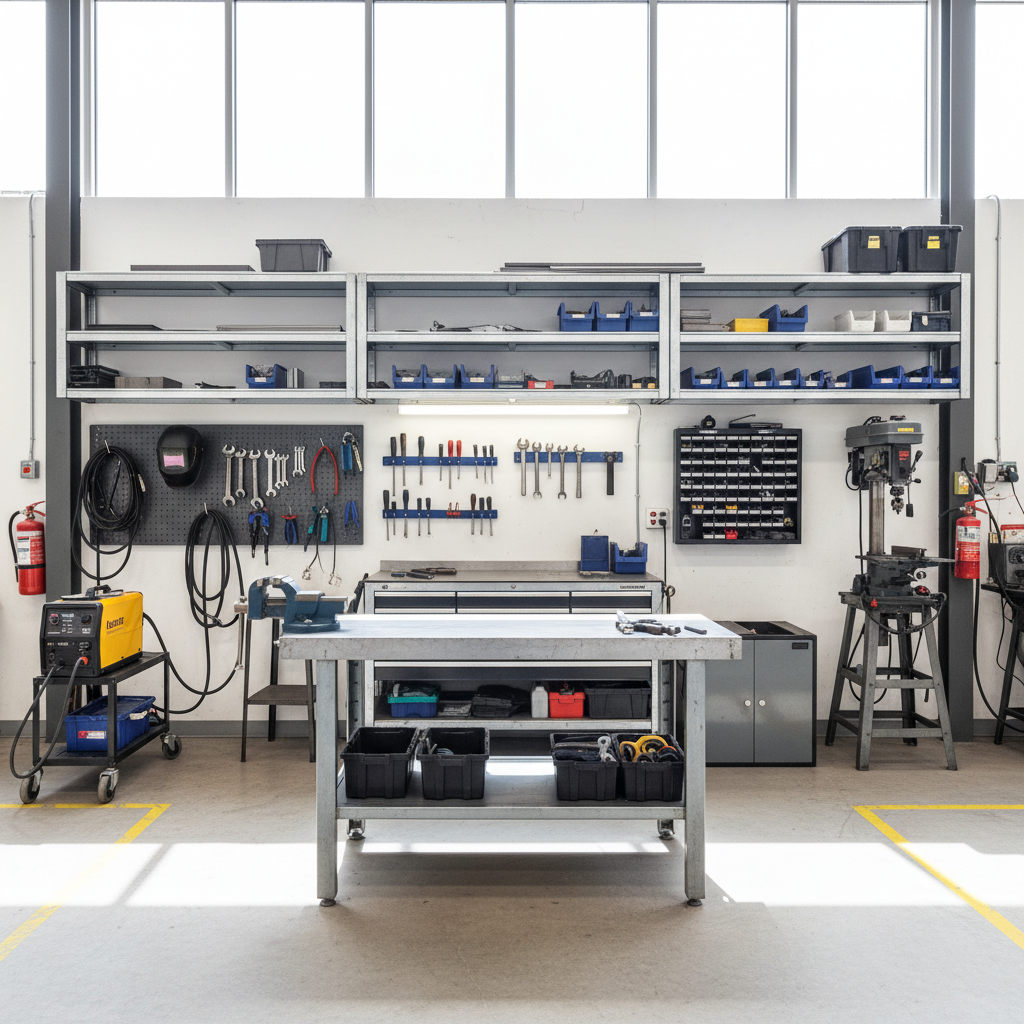

When setting up a metal workshop, selecting the right tools and equipment is crucial for efficiency and productivity. Essential tools include a sturdy workbench, which provides a stable surface for cutting, welding, and fabricating metal components. A reliable set of hand tools, such as wrenches, pliers, and screwdrivers, are vital for basic assembly and maintenance tasks. Moreover, investing in a high-quality MIG or TIG welder will elevate your ability to join metals, offering versatility for various projects.

Safety equipment cannot be overlooked when organizing your workshop. A properly fitted welding helmet and gloves are essential to protect against burns and sparks. Additionally, a quality respirator helps to safeguard your lungs from harmful fumes and particles during metalworking processes. Furthermore, having a well-stocked first-aid kit and a fire extinguisher nearby is necessary for ensuring a safe working environment. Lastly, incorporating storage solutions such as shelving units and toolboxes will help keep your workshop organized, making it easier to locate tools and materials when needed.

Effective Organization Techniques for a Productive Workspace

Creating an efficient metal workshop requires a strategic approach to organization that optimizes workflow and enhances productivity. According to a report by the National Association of Manufacturers, well-organized workspaces can boost productivity by up to 25% as employees spend less time searching for tools and materials. Implementing effective organization techniques, such as using designated storage solutions for tools and materials, can significantly streamline operations. For instance, tool shadow boards allow every item to have a specific place, making it easy to locate tools immediately.

Additionally, incorporating clean and organized work areas minimizes the risk of accidents and increases safety, which is a crucial aspect in a metalworking environment. The Occupational Safety and Health Administration (OSHA) emphasizes that cluttered workspaces can lead to a higher number of workplace injuries. By maintaining clear paths and upholding regular cleaning schedules, workshops not only adhere to safety regulations but also foster a culture of efficiency.

Furthermore, using color-coded systems or labels can enhance quick identification, contributing to a more productive earning environment where tasks flow seamlessly from one to another.

Safety Measures and Best Practices for Metalworking

Creating a safe metal workshop is paramount for ensuring productivity and the well-being of metalworkers. A report by the Bureau of Labor Statistics noted that nearly 20% of workplace injuries in manufacturing arise from unsafe environments. Implementing strict safety measures can significantly reduce these risks. First, proper personal protective equipment (PPE) is essential. Workers should be equipped with safety glasses, gloves, and steel-toe boots. According to a study by the National Safety Council, using appropriate PPE can lower the incidence of injuries by over 40%, highlighting its importance in a metalworking setting.

Additionally, an organized workspace contributes to an efficient and safe environment. A cluttered workshop not only reduces productivity but also increases the likelihood of accidents. The Occupational Safety and Health Administration (OSHA) recommends maintaining clear walkways and ensuring that tools are stored properly to minimize the risk of trip and fall accidents. Regular training sessions on the latest safety protocols and equipment usage are also crucial, as they help workers stay informed about potential hazards. By fostering a culture of safety and awareness, metal workshops can operate more efficiently and effectively.

10 Essential Tips for Setting Up Your Metal Workshop Efficiently

| Tip | Description | Safety Measure | Best Practice |

|---|---|---|---|

| 1. Organize Your Space | Arrange tools and materials for easy access and workflow. | Keep paths clear to avoid tripping. | Use labeled storage bins. |

| 2. Proper Lighting | Ensure adequate lighting for detailed work. | Avoid working in shadows. | Use bright, energy-efficient bulbs. |

| 3. Ventilation | Ensure proper airflow to avoid fumes build-up. | Use exhaust fans if necessary. | Keep windows open when possible. |

| 4. Invest in Quality Tools | Select tools that are durable and reliable. | Inspect tools regularly for wear. | Research and read reviews before purchasing. |

| 5. Wear Safety Gear | Protect yourself with appropriate gear. | Use gloves, goggles, and masks. | Establish a ‘no gear, no work’ policy. |

| 6. Use Fire Safety Equipment | Have fire extinguishers available. | Check expiration dates regularly. | Conduct fire drills. |

| 7. Maintain Tools | Regularly clean and lubricate tools. | Avoid rust and wear. | Create a maintenance schedule. |

| 8. Store Materials Safely | Organize metal stock to prevent accidents. | Shelve heavy materials properly. | Use racks for safe storage. |

| 9. Keep a First Aid Kit | Be prepared for any accidents. | Check supplies regularly. | Train staff in first aid procedures. |

| 10. Create an Emergency Plan | Know the steps to take in case of emergencies. | Practice drills regularly. | Display emergency contacts visibly. |

Maximizing Workflow: Layout Tips for Your Metal Workshop

Creating an efficient layout for your metal workshop is crucial for maximizing workflow and productivity. Start by zoning the workspace according to the different tasks involved in metalworking. Allocate distinct areas for cutting, welding, grinding, and finishing. This separation not only prevents congestion but also allows tools and materials to be stored closest to where they will be used. For instance, position welding stations near the material storage area to minimize the handling of heavy metal sheets, which can save time and energy.

Additionally, ensure that your workshop layout promotes easy access to tools and equipment. Arrange frequently used tools within arm’s reach, utilizing wall mounts and pegboards for organized storage. Consider the flow of materials as they move through the workshop; keeping paths clear and ensuring that each station connects logically will improve efficiency. Incorporate mobile workstations where possible, as they provide flexibility to adapt the workspace layout based on ongoing projects or specific tasks, further enhancing productivity and reducing downtime.

Related Posts

-

10 Essential Tips for Choosing the Best Roof Panels for Your Home

-

How to Choose the Best Aluminum Roof for Your Home in 2025

-

How to Choose the Best Sheet Metal Roof Panels for Maximum Durability and Energy Efficiency

-

2025 Top 10 Architectural Sheet Metal Trends for Innovative Design Solutions

-

Top 5 Benefits of Choosing Aluminum Roofs for Homeowners in 2023 with Industry Insights on Longevity and Energy Efficiency

-

Top 5 Benefits of Using Stainless Steel Wall Panels for Modern Interiors